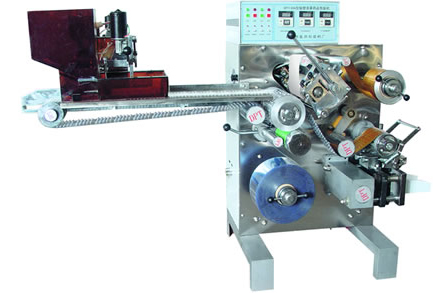

DPT130A型铝塑泡罩药品包装机

发布日期:2018-06-13 15:25:54 点击:14210

DPT130A铝塑泡罩药品包装机是以PVC和PTP为主要的包装材料,适用各种不同规格的素片、糖衣片、胶囊、胶丸及异形片粒状药品。

该机是胆式内加热铝塑泡罩包装机,由于在加热辊表面采用先进的涂氟技术,使PVC受热均匀,泡罩成型挺实。停机、开机不存在丢泡现象,避免包装材料的浪费。吸泡、充填、网纹热封、打印批号、板块冲裁皆可连续作业,无边冲裁可节省包装材料4%-6%。安装调试维修方便、结构合理、紧凑、体积小、重量轻、价格低、是高新技术的结晶。

主要技术参数:

1.包装材料:PVC130×0.25(mm)PTP130×0.02(mm)

2.最大成型深度:15mm

3.冲裁次数:25-30次/分

4.包装效率:4-8万粒/小时

5.耗水量:2.91L/min

6.电源总功率:3.0KW

7.电压:380V/50HZ 22V/50HZ

8.重量:300Kg

9.外形尺寸(长×宽×高):1600×800×1240(mm)

Type DPT130A Aluminum-plastic Blister Packing Machine for Medicine

Type DPT130A aluminum-plastic blister packing machine for medicine uses PVC and PTP as main wrappers, which is applied to different specifications of medicines, such as tablets, sugar-coat pills, capsules, CAP, and abnormal tablets and granules.

It is the gallbladder-type inner-heating aluminum-plastic blister packing machine. Because it adopted the advanced fluorin painting technology on the surface of heating rollers, so PVC can get even heat, and firm molding blister packing. There is no phenomenon of losing bubbles when stops and starts packing. Therefore it can avoid waste of wrappers. Following working procedures can be performed continuously, including absorbing bubbles, filling, wove heating-seal, printing batch numbers and plank cutting. The plank cutting without edges can save 4%-6% of wrappers. Convenient installation and adjustment, reasonable and compacted structure, small volume, light weight and low price, all these are the result of high and new technology.

Specifications:

1. Wrapper: PVC130×0.25(mm)PTP130×0.02(mm)

2. Max forming depth: 15mm

3. Cutting frequency: 25-30times/Min

4. Packaging efficiency: 40000-80000 granules/hour

5. Water consumption: 2.91L/min

6. Total power supply: 3.0KW

7. Voltage: 380V/50Hz 22V/50Hz

8. Weight: 300Kg

9. Dimension (Length × Width × Height): 1600×800×1240(mm)